Description

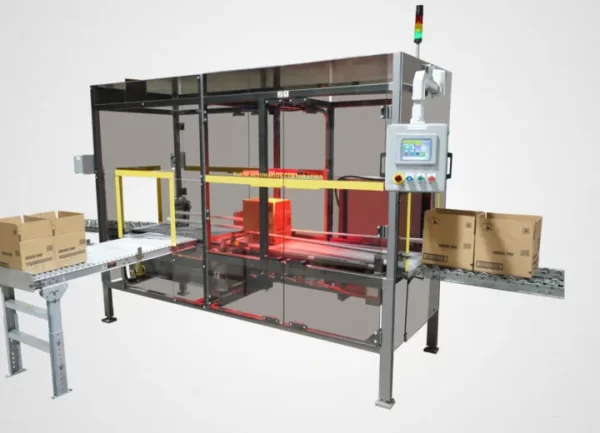

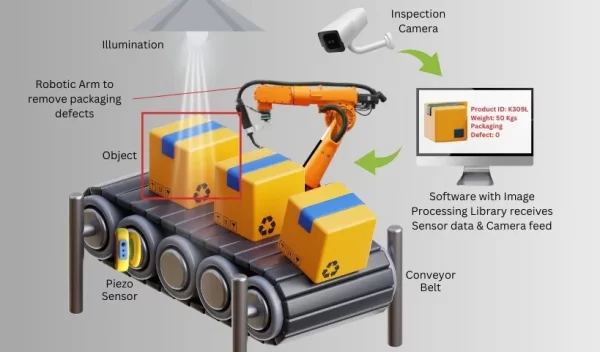

Vision Inspection refers to the use of camera-based systems and image processing technologies to automate the inspection and quality control process in manufacturing and other industries. It involves capturing high-resolution images of products and analyzing them to detect defects, ensure accuracy, and maintain product quality.

Here are key aspects of Vision Inspection:

- Automation: Vision inspection systems reduce the need for manual checks, increasing speed and consistency in quality control.

- High Accuracy: Cameras and sensors detect even the smallest defects, ensuring high precision and reliability in quality assessment.

- Real-Time Monitoring: The system allows for real-time inspection, enabling immediate identification and correction of errors in the production line.

- Versatility: Suitable for various industries such as automotive, electronics, pharmaceuticals, food processing, and packaging.

- Cost-Effective: Reduces the need for human labor and minimizes product wastage, leading to cost savings.

- Integration with Other Systems: Vision inspection can be integrated with other automation systems like robotics and conveyor belts to streamline the entire production process.

- Types of Inspections: It can check for size, shape, color, completeness, surface defects, and barcode reading among other features.

At Helikautotech, we offer advanced vision inspection solutions, enhancing product quality control by providing high-precision, automated inspection systems tailored to meet your manufacturing needs.

Reviews

There are no reviews yet.